At Jota Advanced Engineering we use high quality and high performance machines throughout our entire workshop.

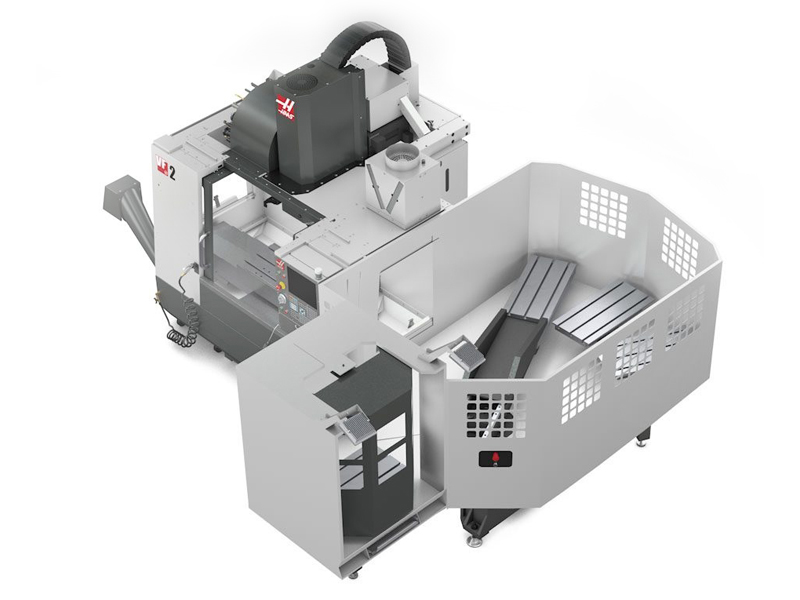

UMC-750 (x2)

Working envelope:

762 x 508 x 508mm

5-axis machines, ideal for multi-sided and complex parts.

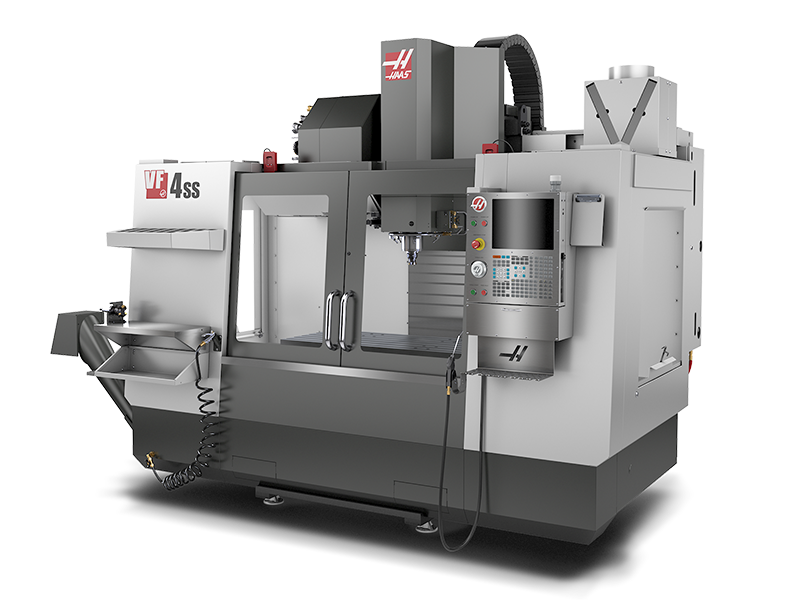

VF-4SS (x2)

Working envelope:

1270 x 508 x 635mm

3-axis vertical machining centres, one includes a 4-axis rotary.

ST-25Y

Working envelope:

298mm Diameter / 572mm Length

This rigid machine has a superior cutting performance, and an enhanced z-axis for further travel.

DS-30Y

Working envelope:

349mm Diameter / 584mm Length

The Y-axis turning center combines dual-spindle turning with C axis, and live tooling. Offcentre milling, drilling, and tapping operations are also possible.

VF-2SS YT (x2)

Working envelope:

762 x 508 x 508 mm

These extended Y-axis, high power, direct drive spindle machines increase our capabilities for travel.

ST-30 (x2)

Working envelope:

533mm Diameter / 826mm Length

Ideal for high-volume output, with these machines we are able to offer high-performance turning centres with a large working envelope.

ST-30Y (x3)

Working envelope:

349mm Diameter / 826mm Length

These lathes offer high performance and high thermal stability. The addition of the Y axis, allowed for secondary milling activities.

ST-10Y

Working envelope:

279mm Diameter / 406mm Length

This compact machine provides a generous work envelope and with the addition of Y-axis and live tooling, allows milling, drilling, and tapping.

ST-15Y

Working envelope:

406 x 356 x 381mm

Enhanced with a faster spindle and higher rapids for improved production output and part finish.

TL-1

Working envelope:

406mm Diameter / 762mm Length

This machine offers precision control and flexibility when working.

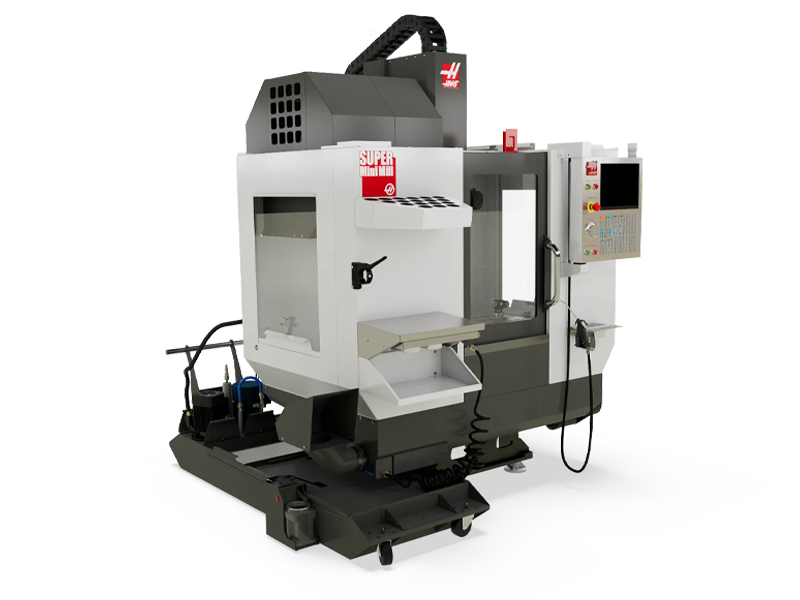

Super Mini mill 2

Working envelope:

406 x 356 x 381mm

Enhanced with a faster spindle and higher rapids for improved production output and part finish.

Aberlink Extol 370

We can perform one-off inspections as well as setup the machines to complete batch inspections.

Aberlink Extol 520 (x2)

With 2 machines we can quickly perform one-off inspections as well as setup the machines to complete batch inspections.

Aberlink Axiom Too HS x 2

Utilising 0.1μm resolution scales on each axis, this is extremely accurate – ideal for measuring tight tolerances. We have 2 on site.

Macsa id iLaserbox 600

Our high definition laser etching machine is used to part number and code products for full traceability.

External processes

To maintain the highest standards of quality, precision, and performance, we can also facilitate a comprehensive range of specialised external processes as required, delivered through our established network of industry-leading partners. These extended capabilities include:To maintain the highest standards of quality, precision, and performance, we can also facilitate a comprehensive range of specialised external processes as required, delivered through our established network of industry-leading partners. These extended capabilities include:

- Anodising – for enhanced surface hardness, corrosion resistance, and improved aesthetic finishes on aluminium components.

- Gear Hobbing – precision machining of gears to high tolerances.

- Heat Treatments – including hardening, tempering, annealing, and stress relieving, tailored to meet specific material and performance criteria.

- Polishing & Electro-polishing – to achieve superior surface finishes, and corrosion resistance.

- Surface Treatments – a diverse range of coatings and finishes engineered to meet functional, environmental, and aesthetic demands.

- Wire Eroding (EDM) – enabling ultra-precise cutting of complex shapes in hard or delicate materials with minimal thermal impact.