ABOUT JOTA

At JOTA, we design and manufacture some of the fastest and most reliable wheel-gun sockets in top-tier motorsport. Proven in WEC, our sockets consistently deliver best in class engagement speed, durability, and repeatability under race pressure.

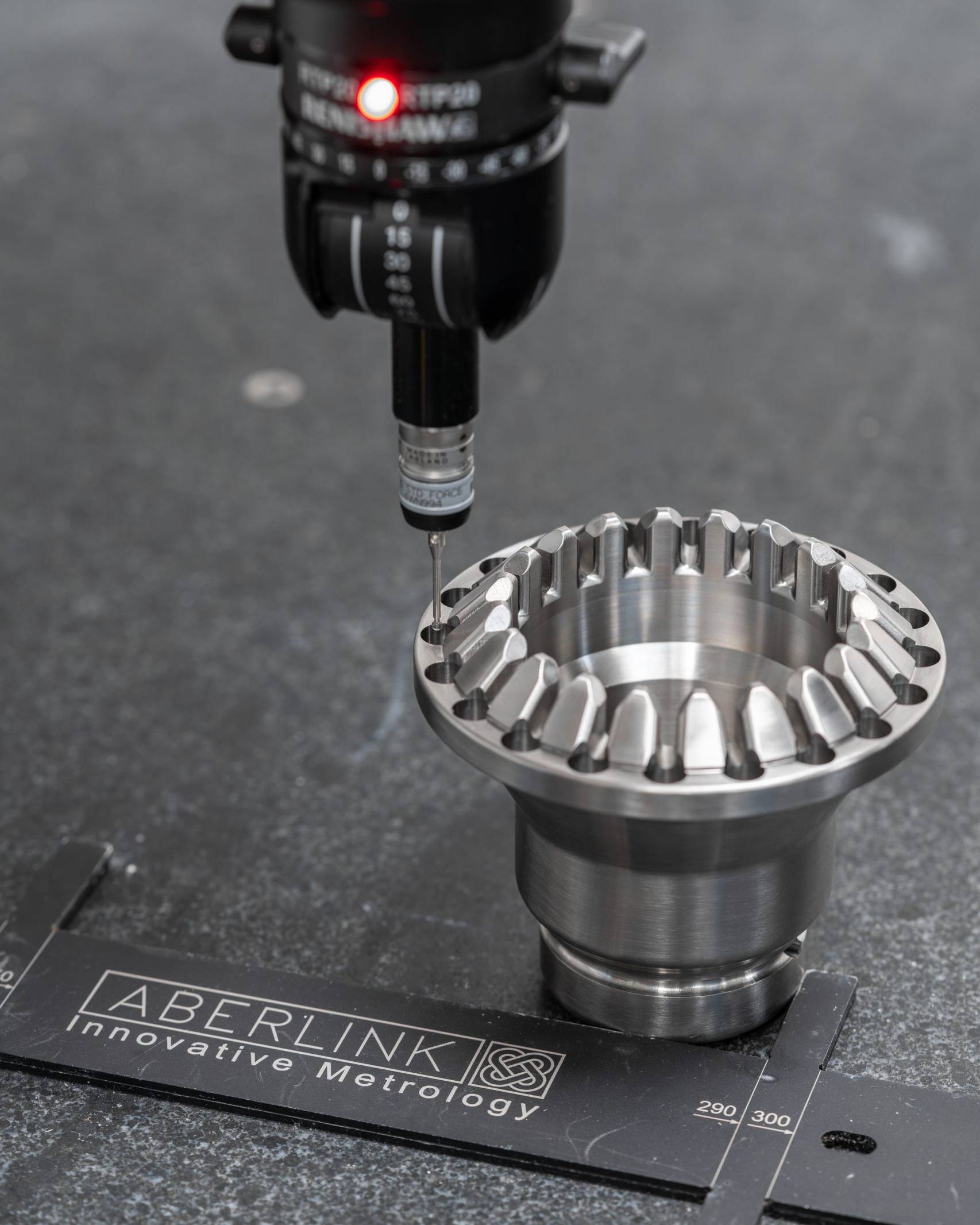

Taking these learnings, JOTA now offers race teams a bespoke socket development programme, pairing your car-specific hardware with our race-winning engineering. Using in-house metrology, rapid prototyping, and precision machining, we develop sockets that maximise:

- Engagement speed

- Repeatability and consistency

- Wear resistance and tool life

- Pit-stop reliability under extreme load

Partner with the JOTA to engineer the next generation of pit-stop performance — and take milliseconds off where they matter most.

JOTA Socket Capability Overview

All sockets are available as square drive or spline drive

Production-ready sockets developed for:

- Oreca 07 LMP2

- McLaren 720S GT3 EVO

- Porsche 911 GT3 R

- Dallara Hypercar platform (Cadillac V-Series.R, McLaren Hypercar, BMW M Hybrid V8)

- Chevrolet Corvette Z06R GT3

- Formula E GEN3 / GEN3 EVO

Sockets currently in development for:

-

Ferrari 296 GT3

-

Aston Martin Vantage GT3

-

Lamborghini Temerario GT3

-

BMW M4 GT3

-

IndyCar Dallara IR-18

-

Formula E GEN4

-

Mercedes-AMG GT3

What we need and how to start

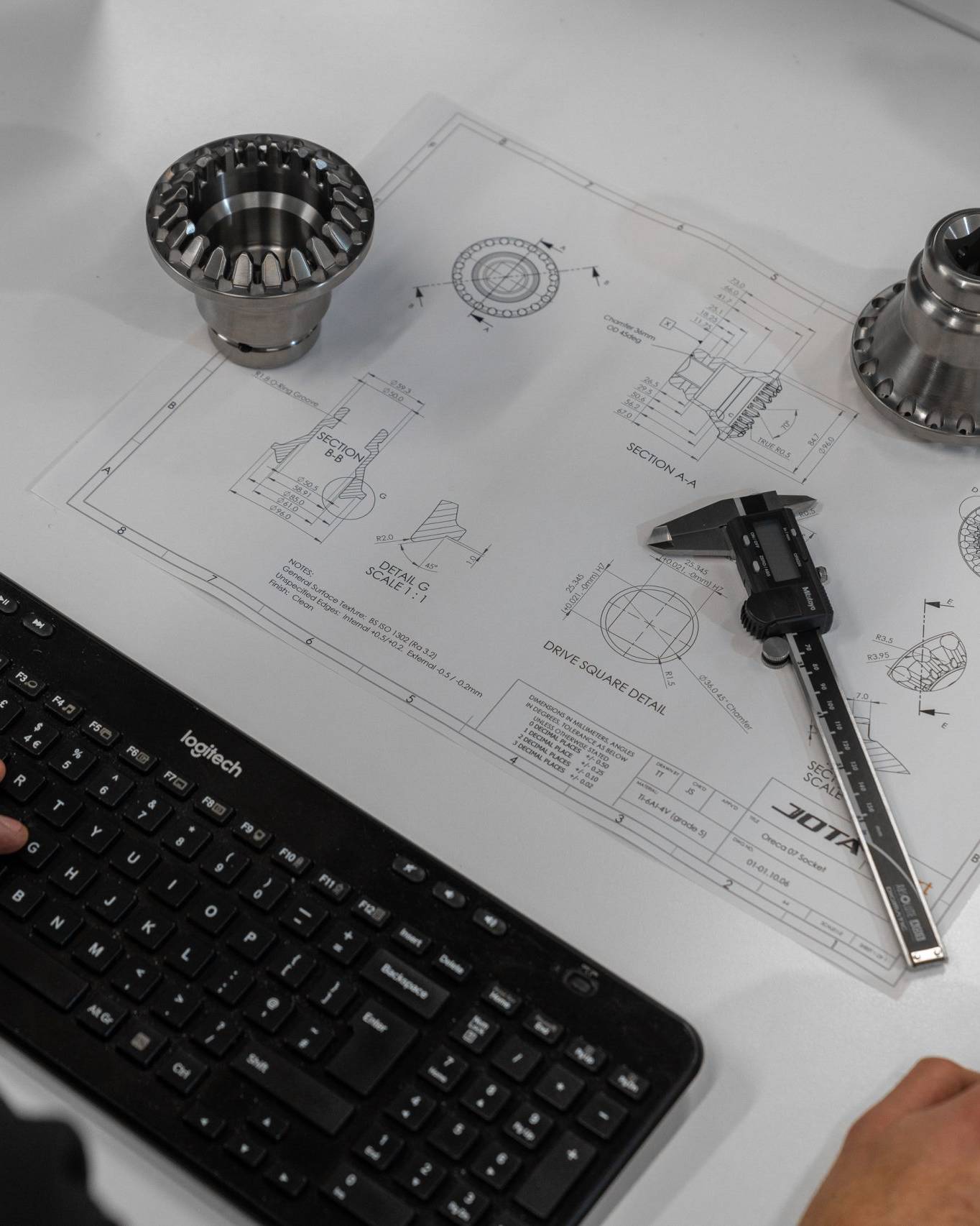

To engineer a bespoke socket, we request:

- Axle (with end cap & safety)

- Wheel

- Wheel nut

- (Optional) Current socket for comparison

All sockets are available as square drive or spline drive

Once received, we run an initial consultation to understand:

- Current socket strengths/weaknesses

- Desired improvements (engagement, wear, weight, consistency)

- Pit-crew preferences and operational constraints

This defines the performance targets for the new socket.

Designing, iterating, perfecting

Our engineering workflow:

- Reverse engineer all supplied components using in-house metrology

- Model the full assembly in CAD

- Evaluate wear surfaces, tooth design, tolerances, magnet details, and engagement geometry

- Produce Nylon 12 prototypes for hand testing and early crew feedback

JOTA guarantees to refine the design until all performance objectives are met.

From metal prototype to track testing

Once approved:

- We manufacture a race-ready metal prototype to final tolerances

- Magnets fitted where required

The team then completes structured pit-crew and rig testing to validate:

- Engagement speed

- Repeatability

- Wear rates

- Crew feedback under rapid-fire use

Final production

When the prototype is signed off:

- We schedule machining in our in-house facility

- All parts maintain identical tolerances and repeatable performance

- Production sockets are delivered quickly

Your final product is a bespoke, race-ready socket engineered around your hardware and pit-stop environment.

Partnership options & commercial terms

Key Development partner options:

Exclusivity

- 6-month exclusive use from delivery of the first metal prototype

- JOTA may promote but will not supply to others during this period

Or

Initial Run Discount

- 10% off your first production order

Key terms:

- Team consents to name/logo use in marketing

- JOTA retains socket design IP

- JOTA signs off all final designs for safety and reliability

- Prototype must be returned after testing

- 50% deposit (minimum 2 sockets) before redesign work begins